Home > Product >SMART-420/560/680

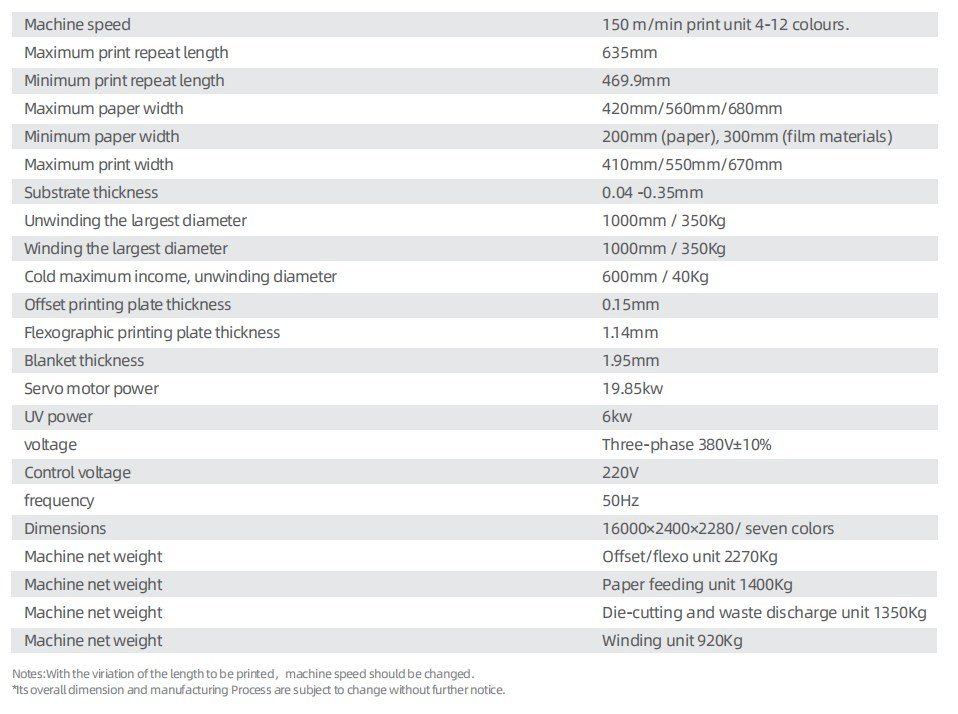

Main Technical Parameters

The machine suitable for several substrate material include sticker ,card board , foil , film and etc. It

adopt inline modular combination method ,can print from 4-12 color. Every printing unit can achieve

one of the printing type include offset, flexo , silk screen, cold foil .

Adopt servo motor control, automatic register system and pre register system to guarantee steady

register in highspeed state 150M/min , Machine has second pass sensor and turn bar function , high

printing quality and steady printing register , it’s an ideal printing machine for all kinds of middle –

high quality daily use chemical , wine label, medicine label , packaging and sticker .

Inline combined printing technology which included offset printing ,flexo printing , silk screen ,cold

foil stamping , lamination and etc . Each function can combined by different printing requirement to

achieve all kinds of label printing.

Large printing area 410x635mm , the max printing repeat can reach 635mm ,Max speed can reach

150 m/minute , it’s the best printing solution for big quantity order and big label .

The range of printing material widely, include paper , sticker , OPP , Bopp, pvc , foil, the thickness of

substrate from 0.04mm (film) -0.35mm (cardboard ).

Servo driver control

Whole machine from unwinding-printing-die cutter -rewinding adopt servo driver technology to get

more accurate tension and register control . Printing tension using closed -loop tension control

system which adopt independent servo driver. Offset printing cylinder, blanket cylinder, impression

cylinder, ink route and water route all use servo driver control to guarantee steady printing, high

printing register and perfect printing quality .

Automatic register system

The register accuracy is 0.05mm ,and can be automatic adjust in axial direction and radial direction.

Pre-register system

The printing cylinder will reach to the register zero point automatic after installing the printing plate

and start work, it can achieve good register requirement without manual control which improve the

working efficiency and save lots of material &labor cost.

Center control screen

The machine parameters can be adjusted and stored at every work order by digital handles which also

contain the machine best state in the printing time , The date can used to setting machine state when

the work order is stored and recalled , and achieve the control to whole machine include the basic

function turning on, turning off ,speed adjustment ,counting ,etc . And also can carry out work storage

and recall , automatic offset ink &water control ,register control and timely quality inspection.

Portable roller technology

Using magnalium printing cylinder and blanket cylinder with double-pinch clamping technology for

easily changing printing area and printing method , convenience operator and low maintenance cost.